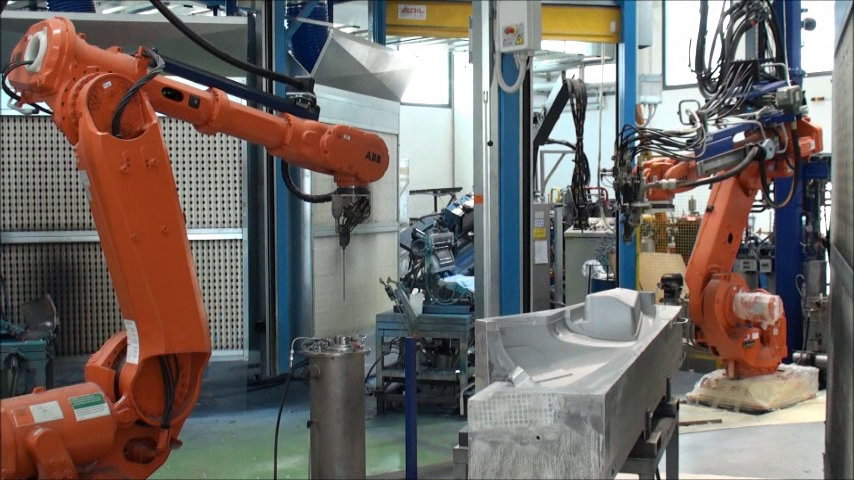

Here at RPS we design and manufacture plastic solutions and components. Our company is a modern and efficient organization rooted in a past full of knowledge and competence. In fact, RPS acquired the assets and know-how of Ruberti, an Italian brand and firm with over a century of history and more than 50 years’ experience in plastic solutions.

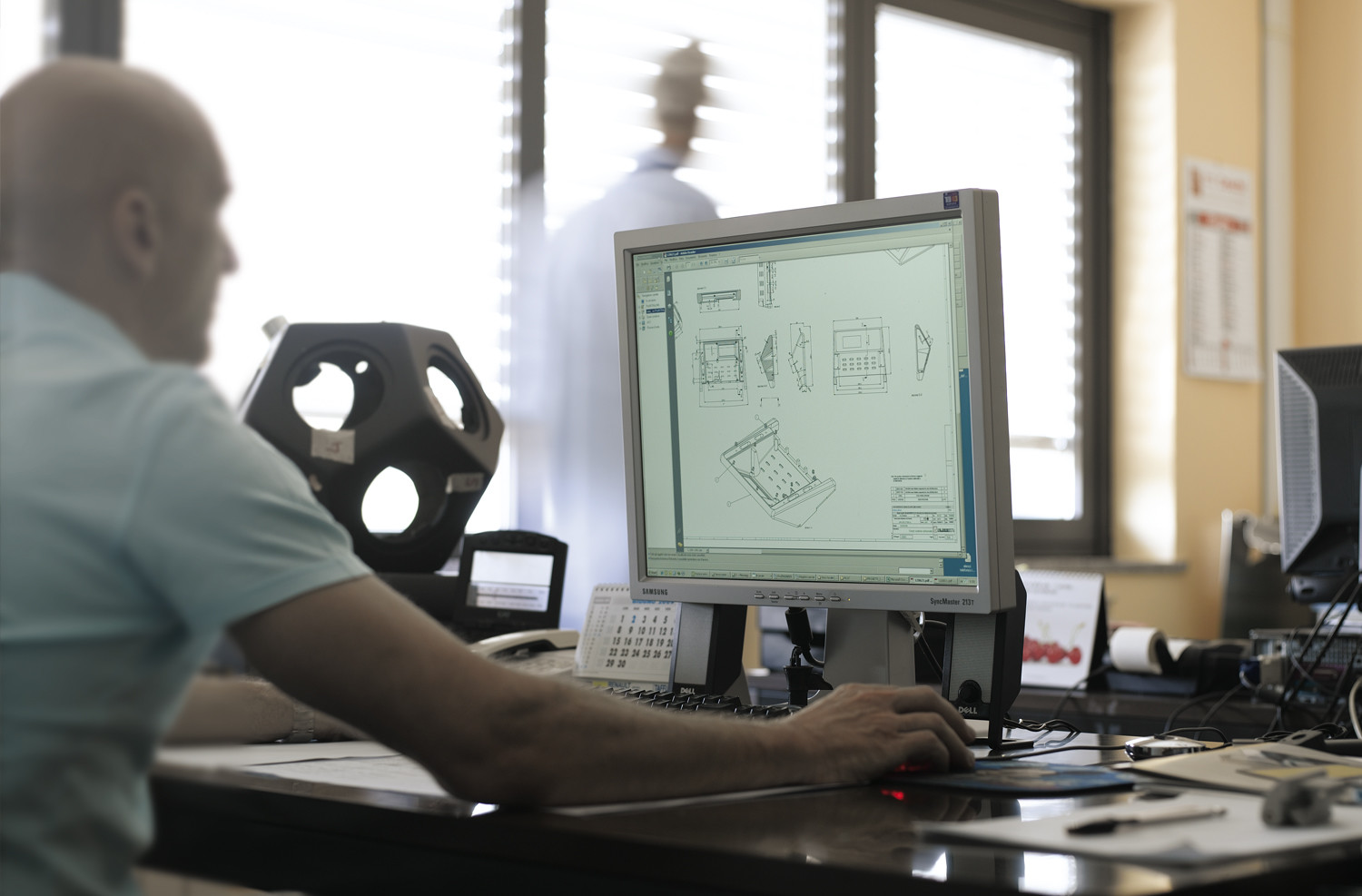

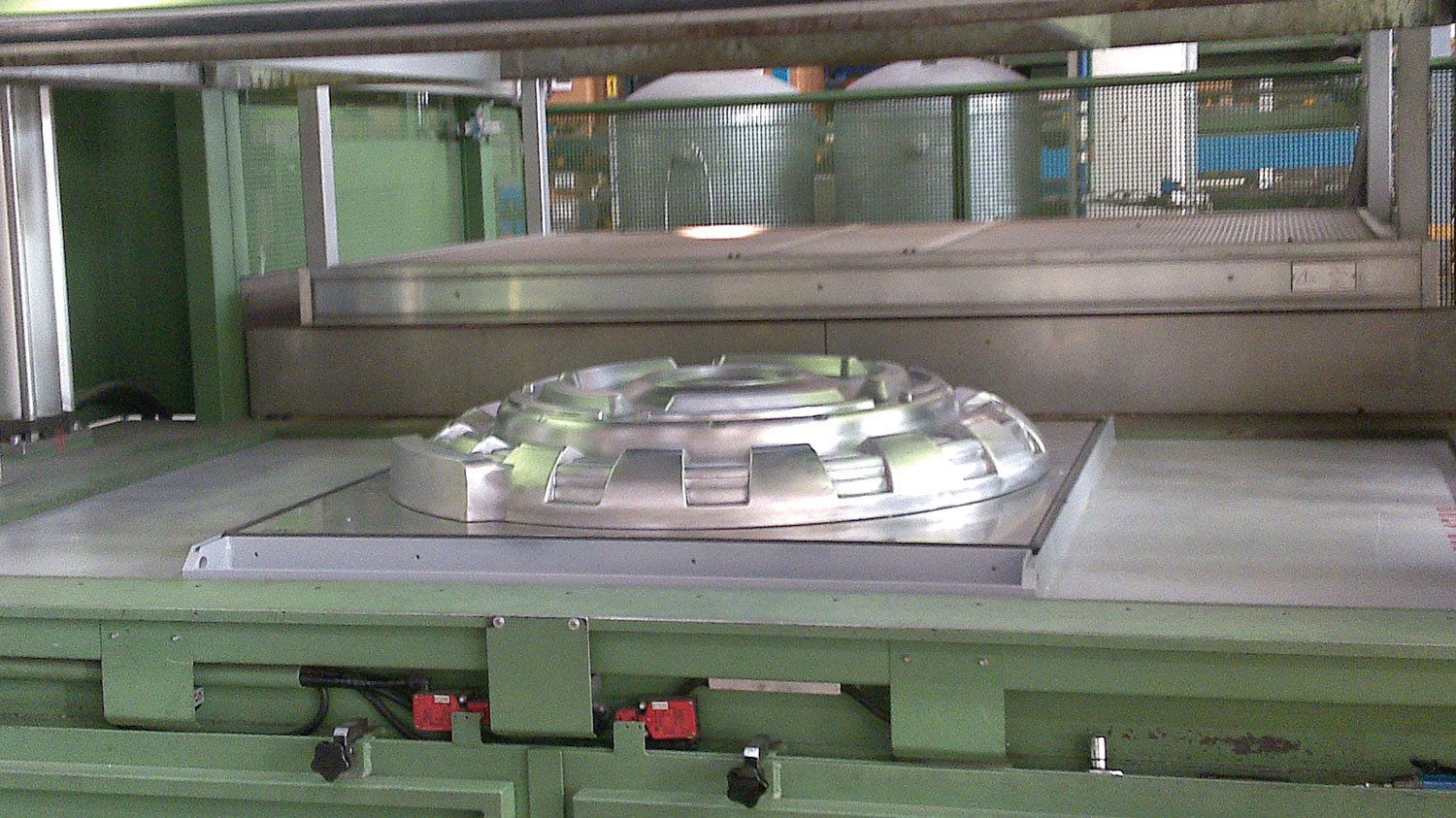

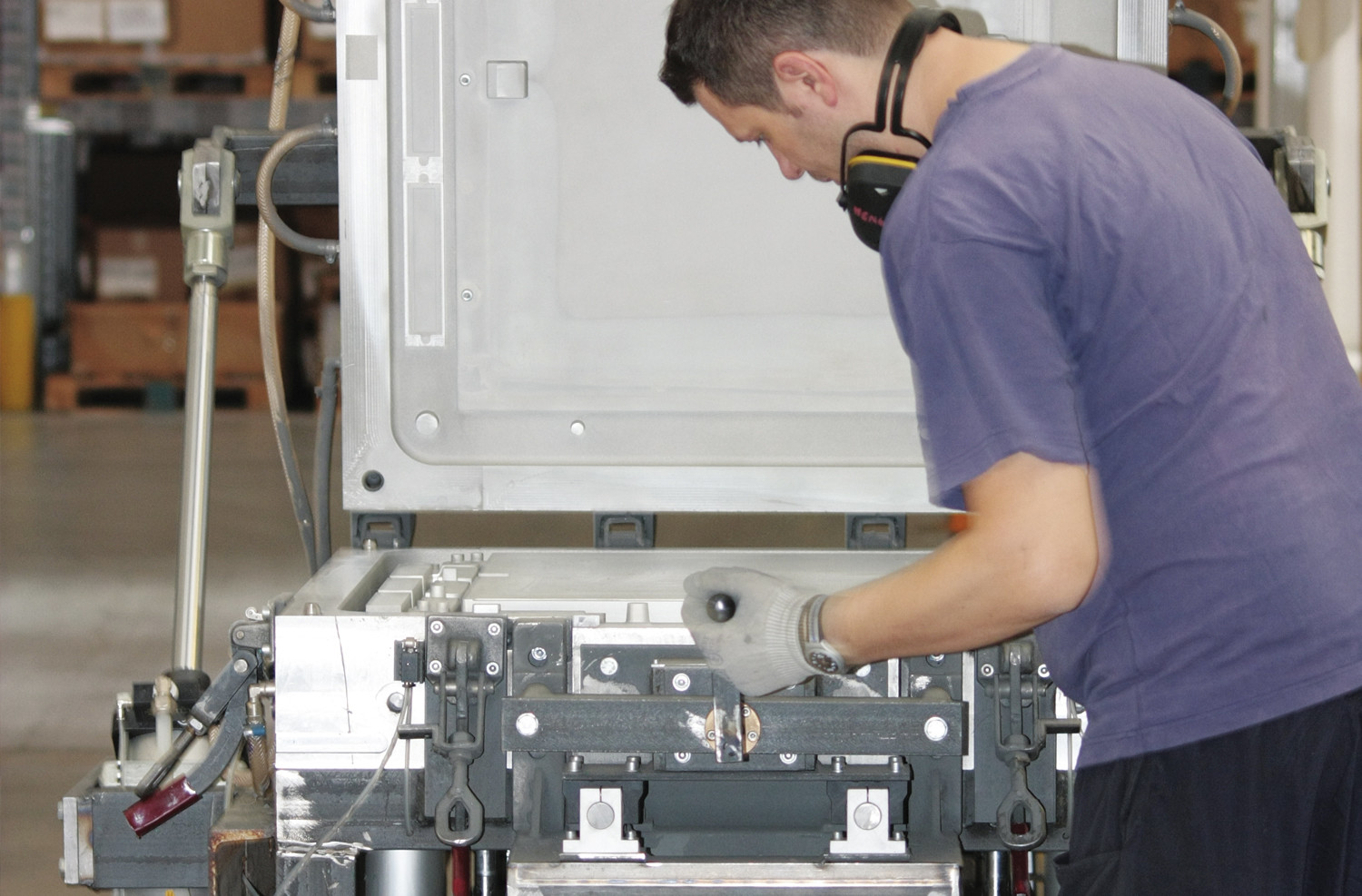

RPS is leader in the production of finished and semi-finished plastic products, applying multiple technologies. We are therefore able to offer continuous assistance and the best support during the entire process: from design to prototyping, up to components manufacturing. We follow thoroughly every project, product and service stage to find the best solution every time and to satisfy any need.